Computer simulations are applied for investigations of complex systems for which simple closed form analytic solutions are not possible. To gain insight into the operation of those systems a simplified model is required. Numerical methods enable the prediction of the behaviour of the model from a set of parameters and initial conditions. Based on results of the computer simulations conclusions for the real system can be drawn.

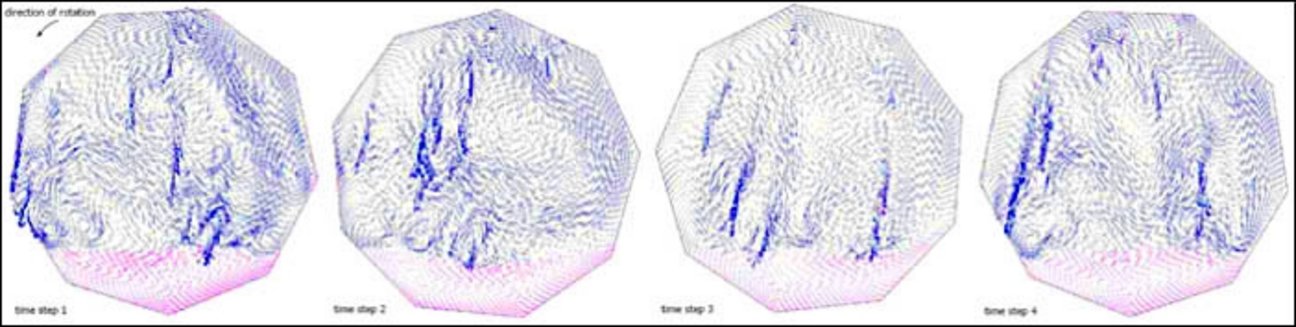

A main effort of the chair of ceramics is to clarify wear mechanisms of refractories. Refractories are used to prevent the steel shell of furnaces and aggregates form high temperatures. In high-temperature processes melts and slags occur. In addition to the thermo-mechanical load the refractory has to withstand the chemical attack of these liquid substances. Thereby the concurrent wear mechanisms are affected by the fluid dynamics of the melts and slags within the aggregate. To investigate this influence of the fluid flow CFD-simulations (computational fluid dynamics) are applied for example in the case of the laboratory rotary kiln that is used to determine the slagging resistance of refractories.

The cost-effective application of building materials is of growing importance, thus measures for optimisations are still of special interest. Computational methods were used to predict the behaviour under their respective boundary conditions. The simulation of the thermo-mechanical behaviour of refractories represents a research area at the chair of ceramics.

Refractories were mainly used in industrial vessels to protect the steel construction from high process temperatures. Theses vessels are widespread, for example in metallurgical industry, glass industry, chemical as well as in the building materials industry. Based on their application, refractory materials reach temperatures of more than 1500°C. Mechanical stresses appear in the lining due to the thermal expansion and the mechanical constraints. These loads facilitate mechanical failure and can accelerate the wear rate of the refractory material and necessitate a premature replacement of the refractory product.

The behaviour of the lining can be improved with adequate selection of the materials, optimisation of geometry or adaptation of process parameters. For this purpose simulations using Finite Element Methods (FEM) are carried out at the chair of ceramics. To clarify failure mechanisms it is necessary to allow for nonlinear material behaviour especially in the course of crack formation.

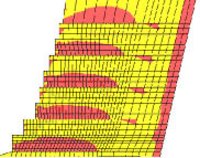

With this numerical tool it is possible to analyse for example the loads in the bottom/wall transition zone of a LD-converter in which carbon-rich hot metal is converted into steel.

The thermal expansion of the lining in the bottom and the wall induces a bending moment in the bricks of the transition zone. At the right side of the figure the stresses in radial direction are shown in a contour plot. Zones with tensile stresses are red and zones with compressive loads are coloured yellow. These bending stresses lead to crack formation parallel to the hot face, which can cause spalling of brick parts.

References

D. Gruber, K. Andreev, H. Harmuth: Optimisation of the Lining Design of a BOF Converter by Finite Element Simulations. Steel Research int. 75 (7), 455-461, 2004

![Abb. 1 (oben): Heiztischmikroskopische Untersuchung<br>der Kristallisation einer Gießschlacke.<br> Die Pfeile kennzeichnen die Cuspidinkristalle [2] csm_Giesspulver_Koelbl_6f0ab5d907](/fileadmin/_processed_/2/8/csm_csm_Giesspulver_Koelbl_6f0ab5d907_23192b774a.jpg)

der Kristallisation einer Gießschlacke.

Die Pfeile kennzeichnen die Cuspidinkristalle [2]

One of the main research interests of the chair of ceramics is the investigation of the structure of mould powders and slags as well as the characterisation of their melting and solidification behaviour. For these purposes original mould powders and samples taken from service (mould slags, slag rims) are analysed.

The therefore applied methods are listed below:

- Reflected light and scanning electron microscope for mould powder, mould slags and samples annealed at selected temperatures (fig. 1 and fig. 2)

- Hot stage microscope (fig. 3 and fig. 4) for investigation of mould powders, polished sections of mould powder specimen, as well as mould slags at temperatures up to 1500°C

- XRD

- Differential thermal analysis and thermogravimetry

- Investigations using the double hot thermocouple technique (DHTT) (fig. 5): There the crystallisation behaviour of a mould slag in dependence of the temperature gradient is observed.

- High temperature viscometer (fig. 6)

The characterisation of mould powders using the methods quoted above makes it possible to draw conclusions concerning operating performance and mould powder selection.

References

[1] I. Marschall, H. Harmuth: “Investigation of the slag rim growth in the continuous casting process”, SCANMET III- 3rd International Conference on Process Development in Iron and Steelmaking, 8-11 June 2008, Luleå, Sweden

[2] N. Kölbl, H. Harmuth: „Hot stage microscopy for in situ observations of the melting and crystallisation behaviour of mould powders”, SCANMET III- 3rd International Conference on Process Development in Iron and Steelmaking, 8-11 June 2008, Luleå, Sweden

Contact: Nathalie Kölbl, Irmtraud Marschall